In the world of electronics and contemporary innovation, the significance of printed circuit boards (PCBs) can not be overstated. These intricate components form the backbone of practically every electronic device, from computers and mobile phones to home appliances and medical tools. A PCB, often described as a motherboard, supplies the necessary framework for connecting numerous electronic parts with conductive tracks etched onto non-conductive substratums. Among the numerous kinds of PCBs, the rigid-flex circuit boards stand out as an impressive advancement. These are hybrid boards that integrate the very best features of rigid and flexible PCBs, permitting vibrant styles that can twist and flex without compromising structural stability. This adaptability makes rigid-flex circuits specifically appealing for applications where space is restricted, such as in mobile tools and wearables.

The production of PCBs, especially in high-density interconnect (HDI) arrangements, has actually progressed as the demand for smaller, faster, and more reliable electronics rises. HDI PCBs integrate finer lines and spaces, as well as smaller vias, which permit for higher component density.

Collaborative endeavors with printed circuit manufacturers are critical in making sure that PCB styles transition efficiently from conceptual stages to real items. These manufacturers specialize in various facets, including PCB assembly and fabrication. They utilize products like FR-4, a flame-retardant epoxy resin, which is extensively related to for its balance of efficiency and cost-effectiveness. In the realm of high-performance applications, variants such as Rogers material, Megtron 6, and Megtron 7 are often used for their premium dielectric properties and high-frequency performance. As a result, printed motherboard assembly (PCBA) ends up being a vital action in the process where various elements are soldered onto the PCB in accurate arrangements to guarantee optimum operation.

Quick turn-around PCB prototyping services have actually acquired appeal as services aim to bring their products to market swiftly. With the enhancing availability of fast-turn PCB services, the obstacles to prototype advancement have been dramatically decreased, making it possible for an atmosphere of advancement.

Flexible printed circuit boards (FPCBs) are an additional remarkable group that has actually gathered focus due to their one-of-a-kind abilities. These boards are designed to be ultra-thin and lightweight, providing the capacity to flex, fold, or twist without jeopardizing performance.

Thermal monitoring, for instance, plays an essential duty in PCB design, particularly in electronic products that run under high tons. Designers should take into consideration materials with excellent thermal conductivity, such as heavy copper PCBs, which assist dissipate warmth efficiently.

The understanding of printed circuit board click here design is essential for designers and product designers. Knowing numerous aspects such as circuit card assembly, which consists of the process of soldering parts onto a PCB, can considerably influence the end product's high quality. Reliable design practices make sure that electrical paths are optimized and that the general format minimizes interference, consequently boosting lifespans and performance. Furthermore, making use of devices and software created for PCB format and simulation can significantly enhance the design process, permitting developers to promptly alter prototypes based on testing results.

Variations in PCB types such as 2-layer, 4-layer, and multi-layer boards are each matched to details applications based on their complexity and the variety of parts that require to be incorporated. Four-layer PCBs give raised directing abilities, crucial for extra sophisticated electronics. These boards aid in handling signal honesty and give ample room to route traces more effectively, making certain even more trusted efficiency in whatever from mobile phones to complicated industrial tools.

Contract PCB assembly services have become an essential resource for companies lacking the internal abilities to deal with intricate assembly processes. These services typically include detailed assistance varying from design appointment here to major production, providing companies with the versatility they require to satisfy differing needs. By partnering with well-known manufacturers, companies can take advantage of proficiency in areas such as HDI layouts, microvias, and multilayer PCBs, thus broadening their product offerings without investing heavily in devices and labor.

Selecting the ideal products for PCB production is vital, and factors to consider usually include the ecological requirements applicable to their use, consisting of UL scores, such as 94V-0, which concerns discharge retardancy. Manufacturers need to stay notified concerning conformity laws to make sure that their products fulfill safety and security criteria while additionally doing efficiently in their intended application environments.

The integration of superhigh frequency (RF) technology right into PCBs is an additional location seeing increased importance, particularly with the surge of cordless interaction tools. RF PCBs need to be very carefully designed, with factors to consider for impedance control and reduced signal loss due to the high regularities entailed. This expertise calls for knowledge of RF circuit design and may include in-depth electro-magnetic simulations as engineers work to accomplish ideal capability in small forms.

As innovation remains to evolve, manufacturers are progressively adopting automation and advanced fabrication processes to enhance efficiency. Technologies such as automated optical inspection (AOI) and surface install modern technology (SMT) are currently standard practices, permitting high-speed assembly and regular top quality control. Advancements in PCB manufacturing likewise reach new products and strategies, such as the usage of embedded technology where parts are ingrained directly within the layers of the PCB, further conserving area and improving performance.

To conclude, the printed circuit card industry continuously adjusts to changing needs and technological innovations, showing the vibrant landscape of electronics. Whether with PCBA, flexible circuits, or fast-turn prototypes, the layouts, materials, and procedures linked with PCBs are vital in shaping the future of electronic tools. Manufacturers that remain at the forefront of these advancements not just boost their one-upmanship but additionally allow the development and advancement of sophisticated innovations that define modern-day life. With the ever-increasing complexity of circuits and the demand for efficient, high-performance services, the PCB sector stays a foundation of technical development, driving the means we communicate with tools and ultimately linking our digital and physical worlds.

Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Seth Green Then & Now!

Seth Green Then & Now! David Faustino Then & Now!

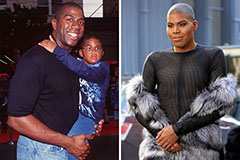

David Faustino Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now!