Aluminum profiles are a vital part in numerous sectors due to their convenience, toughness, and light-weight nature. Among the most acknowledged usages of aluminum profiles is in home window and door production, where aluminum extrusion profiles use an equilibrium between toughness and appearances.

Aluminum profiles for solar panel mounting have actually obtained considerable traction as the demand for eco-friendly energy sources continues to climb. Additionally, since aluminum is totally recyclable, it straightens with the lasting practices encouraged in the solar sector, making aluminum profiles for solar mounting not simply functional however additionally ecologically pleasant.

Industrial applications have also widely welcomed aluminum profiles due to their phenomenal residential or commercial properties. These profiles are commonly combined with CNC machining aluminum profiles, which better boost their capabilities by supplying precision-engineered parts that substantially contribute to modern production procedures.

In the world of thermal monitoring, extruded aluminum heatsinks offer important solutions to maintain electronic devices and mechanical systems cool down. Extruded aluminum heatsinks are defined by their high thermal conductivity and lightweight qualities, making them an ideal option for cooling down applications in numerous electronic and industrial tools.

An additional amazing development in the area of aluminum extrusions is the growth of T-slot aluminum extrusions. This functional framing system enables fast setting up and disassembly, making it excellent for building custom frameworks such as workstations, safety and security guards, and present stands. The modularity of T-slot systems develops countless configuration possibilities, streamlining the layout procedure and facilitating changes as needs evolve. With added parts like ports and brackets, users can conveniently change their arrangements without the requirement for specialized tools or extensive labor.

Standard aluminum extrusion profiles offer as the backbone for plenty of applications across various industries. The adaptability of aluminum extrusion, combined with the schedule of standard profiles, means that services can streamline their production procedures, decrease lead times, and preserve high-quality results.

Custom aluminum extrusion profiles offer organizations the chance to produce tailored remedies that specifically satisfy their unique specifications. Manufacturers that specialize in producing custom aluminum extrusions can suit a large variety of coatings, shapes, and measurements, opening brand-new opportunities for design creative thinking.

In the realm of visual appeals, architectural aluminum extrusion profiles add substantially to modern building layouts. From smooth façades to dynamic architectural components, these profiles offer themselves to ingenious architectural attributes. The here capability to plate aluminum surfaces boosts both the aesthetic allure and toughness of the profiles, adding a layer of security versus rust and surface area wear. This finish not just extends the life expectancy of the profile however additionally provides a myriad of color alternatives, enabling designers to attain a cohesive design aesthetic that straightens with their vision.

Automotive aluminum extrusions are engineered to fulfill specific efficiency requirements, including collision security and mechanical strength while lowering general vehicle weight. The recyclability of aluminum sustains sustainable development objectives, making it a preferred product in contemporary automotive design.

The aerospace sector, recognized for its stringent needs and performance standards, has actually also located aluminum extrusions get more info to be exceptionally valuable. Aircraft aluminum extrusions offer the needed strength while keeping low weight, vital consider trip performance and gas effectiveness. Manufacturers focus on generating premium aluminum extrusions that can endure the high-stress atmospheres linked with air travel, making certain safety and dependability. The transformative nature of aluminum design allows aerospace designers to create ingenious frameworks that boost overall aircraft efficiency.

For recreation applications, boats aluminum extrusion profiles give the architectural honesty needed to withstand varying environmental conditions while adding to weight savings that enhance performance on the water. Using aluminum in marina and boating applications has gained popularity due to its resistance to corrosion from saltwater, making it an exceptional choice for resilient toughness on boats and luxury yachts. The lightweight yet strong characteristics of aluminum permit boosted rate and handling, enhancing the general boating experience.

Aluminium frame manufacturers offer a mix of layout convenience and efficiency, allowing a wide range of items to be created for various get more info markets. From greenhouses to exhibition stands and mechanical assemblies, aluminum structures offer robust assistance while allowing convenience of setting up and modification. The consistent buildings of aluminum make sure that these frames will certainly supply regular performance while maintaining production prices workable as a result of fast production processes.

As we aim to the future, technological innovations and industry advancements will continue driving the growth of aluminum profiles and extrusions. The continuous development of CNC machining techniques additionally enhances the abilities of aluminum profiles, permitting for remarkably elaborate styles that were formerly impractical. Additionally, the expanding need for sustainability techniques will promote a lot more reliable manufacturing processes and greater recycling efforts within the aluminum sector.

Given the wide variety of applications for aluminum profiles-- from building and automotive to aerospace and renewable resource-- it's clear that these products are indispensable to modern-day infrastructure, technology, and sustainable advancement. By leveraging the special properties of aluminum and utilizing the power of sophisticated production strategies, sectors can continue to check out brand-new frontiers and press the limits of layout, efficiency, and effectiveness. Aluminum extrusion continues to be a foundation of modern production, adding to ingenious services that meet culture's developing demands.

Rick Moranis Then & Now!

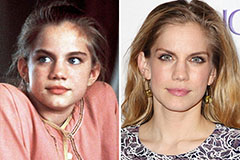

Rick Moranis Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now!